The 15-Second Trick For Road Plate

Table of ContentsRoad Plates - The FactsThe 8-Minute Rule for Road PlatesNot known Details About Road Plates Some Ideas on Steel Road Plate You Need To Know

1. Load-Bearing Capacity: Steel roadway plates have a high load-bearing capability, making them suitable for heavy vehicles and equipment.Recyclable: Steel is a recyclable product, making steel roadway plates an eco pleasant choice. Cost: Steel road plates can be much more pricey than other options such as plastic roadway plates. Noise: Steel road plates can produce more sound compared to plastic road layers when lorries pass over them.

Damages: Steel road plates can come to be damaged or dented if they are not properly kept, which may reduce their load-bearing ability as well as make them risky for use (road plate steel). A plastic road plate is a short-lived cover made use of to cover trenches, ditches, or utility cuts in roadways and freeways. It is made of a plastic material as well as offers the same objective as a steel roadway plate.

They are also commonly more affordable than steel plates and supply a short-term remedy for road work or maintenance tasks. Some plastic road plates are made from recycled materials, making them an environmentally friendly choice. Nonetheless, they might not be as resilient as steel plates and also may not appropriate for rush hour or longer-term use.

6 Simple Techniques For Road Plate Steel

Lightweight: Plastic road plates are lighter than steel plates, making them much easier to handle and also install. Plastic roadway plates are frequently less costly than steel plates, making them an affordable remedy for road job or maintenance jobs.

Reduced Noise: Plastic roadway plates are quieter than steel plates, making them an excellent choice for areas with sound restrictions. Plastic road plates might not be as sturdy as steel plates and may not appropriate for heavy website traffic or longer-term use. 2. Load-Bearing Capability: Plastic roadway plates might have a lower load-bearing capability compared to steel plates, making them improper for hefty cars and also equipment.

For a complimentary quote on any of our crane hire solutions for your next project contact us today by providing us a phone call or filling out our on-line form. Required road plates to cover up a momentary excavation, birthed opening or trench? That's why we put together this detailed overview including just how much weight they can hold, what material you should opt for as well as the different kinds of roadway layers you can utilize.

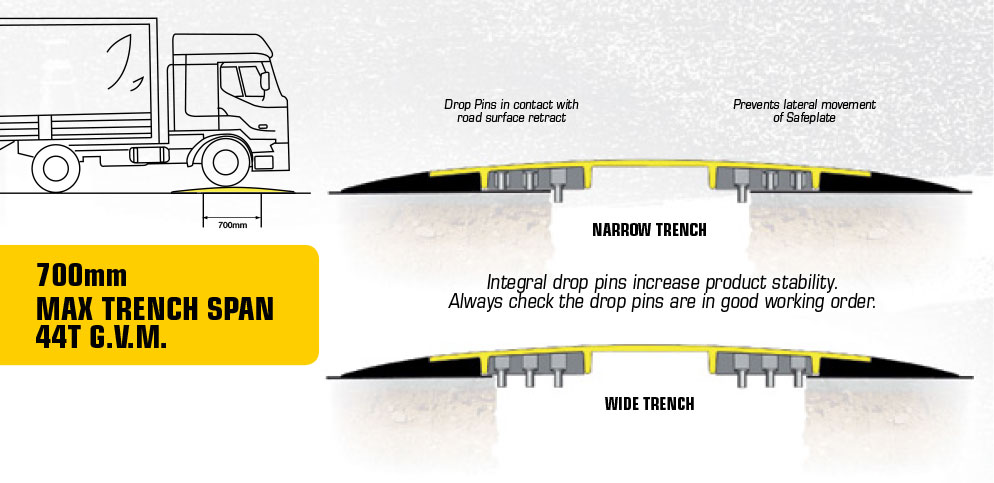

They not simply made use of in sidewalk areas yet can be made use of for carriageways as heavy-duty road plates additionally have the ability to tackle the weight of a 44-tonne car (steel road plate). Road plates are available with a dealt with skid-resistant surface, along with unattended depending upon the situation that they are needed for.

The Single Strategy To Use For Road Plate

The weight of the plate itself depends on the small dimension density of the plate called for to cover the excavation whilst keeping a risk-free tons bearing capacity. It deserves noting that composite road plates are considerably lighter than steel road plates meaning that they can be by hand mounted unlike steel plates which call for a HIAB or heavy-lifting machinery.

Steel plates likewise tend to bend as well as warp in time whereas plastic road plates offer a solution which is far more resilient. To find out more, see our guide on steel roadway plates vs plastic road layers. Right Here at Oxford Plastics, we provide a range of roadway plates to cover temporary excavations.

Figure out even more regarding our exciting series of trench covers and road plates in our best guide, or, for a study on the successes of using road plates for your business, see our detailed situation study for a few of our reliable Germany clients. To find out more on purchasing roadway plates and trench covers, obtain in touch with a member of our professional group. Road plates are safety covers which seal off potentially hazardous openings as well as excavations on a building site or for roadworks. Both are durable as well as can be utilized in a range of applications, there are some crucial distinctions between them which are crucial to take into consideration when picking which fits ideal with your needs.

The 7-Second Trick For Road Plate

Below are some vital differences in between steel and GRP road plates as well as their benefits and drawbacks. The major difference between the two kinds of road plate is weight.